MX Grid

Decentralized edge processing for increased OT efficiency and performance

Extending edge intelligence

MX Grid is the world’s first on-premises, hyper-connected and distributed AI/ML platform offering decentralized and orchestrated processing capabilities and decision-making closest to the data source.

Extending compute power and intelligence over Nokia one platform for industrial digitalization

MX Grid extends the compute power and intelligence of your on-prem Nokia MX Industrial Edge. By using local processing performed even closer to the source, you can embrace the transformative potential of AI and enhance OT efficiency, performance, scalability, agility, reliability and cost-efficiency.

How it works

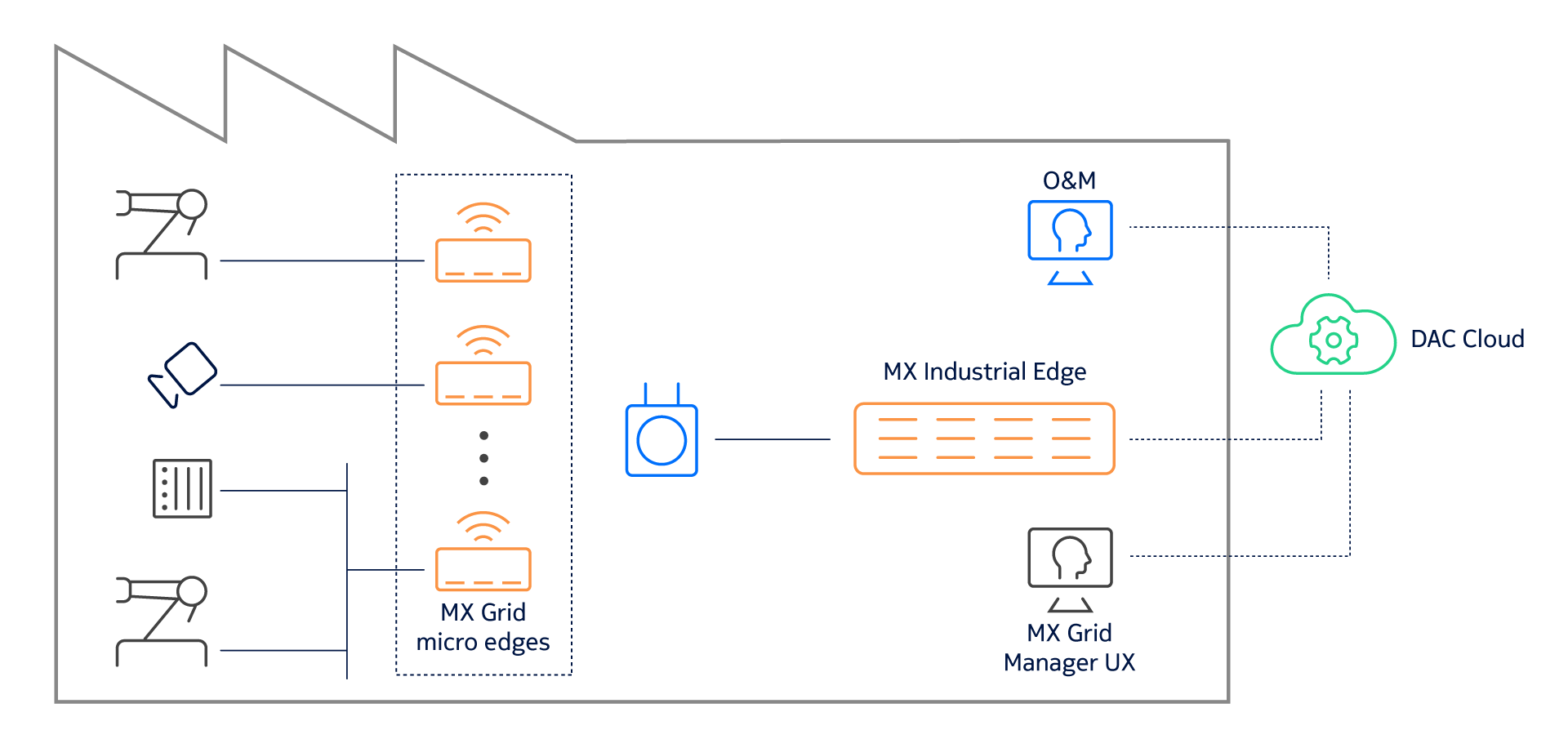

Nokia MX Grid leverages a pool of orchestrated compute-capable field devices (micro edges), that process OT data near to the source using a specialized lightweight AI/ML-capable software stack working in synergy with the on-prem Nokia MX Industrial Edge (MXIE). This creates a robust edge computing infrastructure for applications serving diverse Industry 4.0 use cases. Compute capacity with AI/ML capability can be distributed over the industrial campus, to where it really matters.

- MX Grid micro edges are compact AI-enabled devices that can be deployed in quantities scaled to the need to collect and analyze OT data streams such as sensor data, IoT data, video/acoustic feeds etc., to facilitate real-time monitoring and control applications.

- MXIE – the on-prem OT edge that runs resource-intensive applications and complex AI models. It acts as a central hub to aggregate data from multiple sources, including MX Grid devices.

- MX Grid micro edges are orchestrated by MX Grid Manager running in DAC Cloud. MX Grid Manager acts as the central hub for device, software, application and ML model management, providing a seamless control and administration experience for users.

Use cases

Process monitoring / Predictive maintenance

Simplify OT data collection and standardization from multiple sources using MX Grid sensor aggregation. Identify potential equipment failures or performance issues in advance to schedule timely maintenance, reduce downtime, and optimize resources by collecting and evaluating sensor data at the closest possible point to the source using AI/ML algorithms.

Worker safety

Worker safety is one of the highest priorities for any industrial business. Integrate and process connected worker data, situational sensory information and video feeds using MX Grid by onboarding applications such as Nokia Visual Position and Object Detection to provide significant advantages and highly scalable worker safety systems.

Quality assurance

Maintain high-quality production standards through stringent quality control in your manufacturing processes. Using MX Grid OT data and real-time video feed collection, and AI/ML processing managed at the nearest point to the shopfloor, you can detect deviations in real-time and trigger prompt corrective actions at the production line, thus reducing waste.

Benefits

Process where it makes sense

Benefit from faster, more effective, responsive and agile decision-making by running decentralized workload processing nearest the data source.

Reduced operational complexity

Benefit from fully orchestrated managed operations to simplify both end-to-end management and use case implementation using low-code programming.

Ecosystem neutrality

Data and format agnostic for broad industrial use case support

Optimized TCO

With an easy to scale, as-a-service subscription-based business model that provides investment flexibility at a low-cost entry point.

Emerging use case scenarios

Decentralized workload processing enabling ultra-low latency use cases and efficient network utilization.

Talk to a Nokia expert

Please complete the form below.

The form is loading, please wait...