MX Industrial Edge

Accelerate your digital transformation and harvest value from your OT data

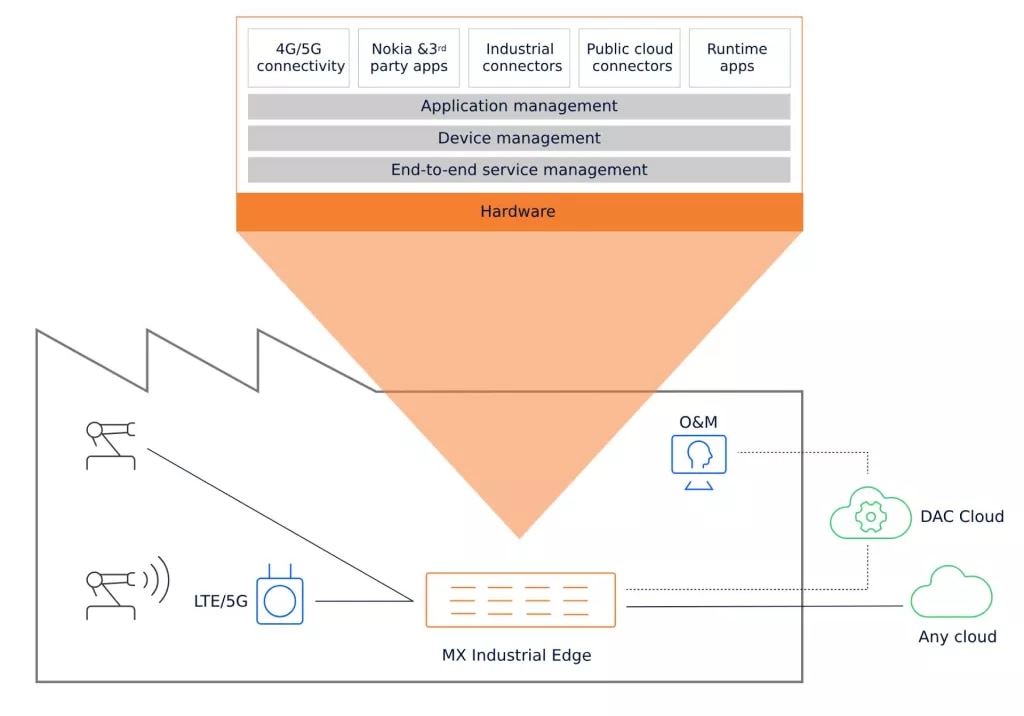

Nokia MX Industrial Edge is a ruggedized, high-performance, resilient, and secure on-premises operational technology edge solution designed to meet the mission-critical needs of asset-intensive industrial environments.

Reliable, secure, real time OT data processing with on-premises edge application platform

Industry 4.0 transforms asset-intensive industries through the digitalization of processes and systems across the entire OT environment, resulting in an explosion in the volume and velocity of raw operational data from machines, sensors and workers.

To harvest real value from this data, industries need a compute solution that helps to reduce llot complexity, has high processing capacity, ensures data security and sovereignty, meets the latency needs of industries' mission-critical OT processes and capable of running various industrial applications based on customers needs.

Only a resilient on-premises edge solution can meet the mission-critical needs of OT processes:

- Real-time processing

- High availability and high reliability

- Alignment with OT security requirements

- OT data sovereignty

- Ecosystem neutral application platform

First off-the-shelf, ecosystem neutral, mission-critical Industrial Edge

One-stop-shop for digitalization applications

- Ecosystem-neutral approach with applications from several industrial ISVs

- Unique Industrial Application Catalog with click-to-deploy simplicity

- Integration capabilities give enterprises the choice to onboard a new breed of OT applications

- Tools to enable faster and smoother application onboarding

Connect all your OT layers, systems and cloud

- Inherent industrial and public cloud connectivity

- Unparalleled flexibility for swift adoption of edge innovations from public clouds

- Integrated solutions from leading industrial solution providers

Wireless connectivity options

- Various private wireless connectivity options to connect all digitalized assets - including LTE/5G and Wi-Fi

- Simplified IIoT complexity with one pervasive communication layer

- End-to-end, pre-integrated solution including industrial devices, connectivity, applications and management

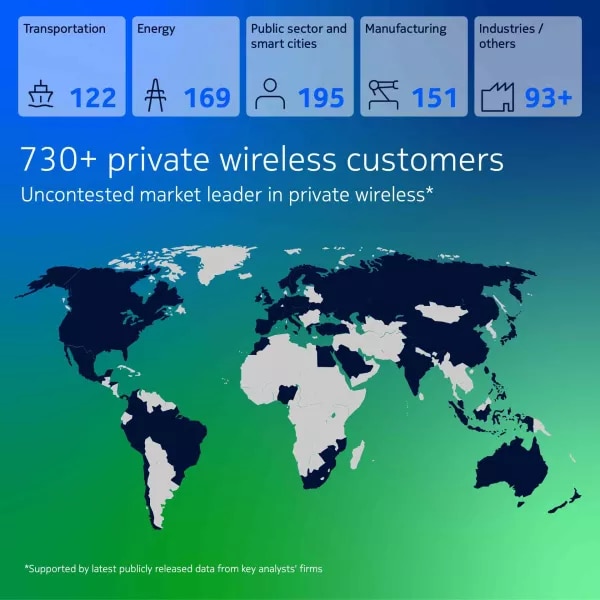

Industry preferred; most adopted private wireless vendor

- Recognized by all the top analysts as the undisputed leading private wireless vendor

- Over 50% market share

- 30 + years of enterprise critical networking experience

- 730 + private wireless customers in all industrial segments

Why Nokia MX Industrial Edge?

Accelerates speed to business value

Delivered as an off-the-shelf, fully pre-integrated, cloud-managed solution, it offers instant 'click-to-deploy' industrial applications and access to multiple complementary hyperscale and industrial cloud ecosystems. By enabling data-driven operational excellence, it supports augmented and automated decision-making, which is key to achieving business goals with Industry 4.0.

High availability and industrial grade system reliability

Ruggedized design with extreme resiliency and reliability for mission-critical OT. Able to operate even if internet connectivity is down. Geo-redundant option for fast disaster recovery.

Optimized TCO

Offers a grow-as-you-need, scalable, as-a-service subscription-based business model that provides enterprises with a low-cost entry point.

Leading edge innovations on-premise

With Nokia MXIE, you can deploy cutting-edge technology enablers such as GenAI LLM to bridge the communication gap between humans and machines. It also supports distributed intelligence and decision-making, as well as advanced multipath connectivity designed for complex industrial environments to enhance connection performance and reliability.

Easy to manage

Fully orchestrated and managed solution comes off-the shelf, fully pre-integrated.

Centralized, efficient, and easy-to-use Operation and Maintenance self-service portal removes the need for complex operation support systems. Simplicity of multi-site management through a common platform.

Futureproof and scalable platform

High performance, high capacity on-premises processing for all your complex industrial OT workloads with cloud-based service management and industrial application catalog offering the latest innovations for industry digitalization.

FAQ

Mission-critical operations require very high availability (>99.99%) and resiliency especially for worker safety or real-time machine control applications that cannot be fulfilled by normal IT service levels, especially when processed externally in the cloud. Beyond that the availability and reliability of remote cloud-based solutions are heavily dependent on the quality and the capacity of the internet link.

Answer:

Our Nokia MX Industrial Edge on-premises solution can work even without the availability of an internet link as all business and mission critical processing occurs on-site. Public internet connectivity disruptions do not impact mission critical data processing.

Our solution can be made even more resilient deployed with geo-redundant architecture for disaster recovery.

Mission-critical operations - like worker safety or real-time machine control - require very low latency (>10ms). In case of remote cloud-based processing the geographical distance increases latency (every 100km distance adds 1 ms), while network service reliability diminishes.

Answer:

Our MXIE on-premises edge solution processes all data locally - eliminating latency and reliability degradations to meet the requirements of mission critical operations. This true real-time control increases productivity and reduces waste.

In my current environment I’m collecting data from diverse, siloed IIoT systems and I need to manage complexity relating to different industrial protocols and data processing applications.

Answer:

Our Nokia MXIE on-premises edge solution simplifies IIoT use-case integration and unifies industrial workloads with "click-to-deploy" applications. Edge orchestration tools offer simplicity through automated application lifecycle management and ensure new security, stability and feature updates are deployed to the platform.

Industrial data analytics solutions often run in the remote cloud - so my sensitive OT data is carried over the internet and processed in a remote compute facility – beyond my control.

Answer:

By deploying edge compute physically on-premises, sensitive OT data never leaves the site, but instead is securely processed on-premises.

OT vendors often create edge solutions that don’t support ecosystem neutrality meaning only applications from the system vendor can be deployed. Because of this lock-in solutions from other vendors can’t be used.

Answer:

Our Nokia MXIE on-premises edge solution supports ecosystem neutrality enabling the deployment of a wide ecosystem of applications in several categories from various vendors.

Most industrial sites are brownfield environments with multiple legacy systems from multiple vendors using bespoke ad-hoc processing units (PC, PLC).

Answer:

Our MXIE on-premises edge solution offers a range of click-to-deploy applications allowing our customers to benefit from protocol translation. With partner applications like Crosser or Litmus, data from different sources can be collected, standardized and analyzed.

How it works?

Nokia MX Industrial Edge can be deployed in any industrial environment to run application workloads that power I4.0 use cases.

It can also be deployed with the Nokia DAC private wireless connectivity solution whereby the control functions of the 4.9G/5G private network will be one of the applications running on Nokia MXIE.

Simple and robust solution with a single edge configuration:

How to buy MX Industrial Edge?

As-a-Service; global availability

Nokia MX Industrial Edge solution is available as-a-Service in hybrid (server hardware CAPEX+ software OPEX) and full (HW and SW) subscription models allowing more enterprises to lower their upfront digitalization costs and accelerate use case implementation.

The solution is tailored to your mission critical use cases requirements.

What industry analysts say about Nokia MX Industrial Edge?

References

Use case: The DXC Signal Private LTE and 5G solution provides enterprises with cutting-edge monitoring and analytics capabilities, enhanced security, and seamless connectivity.

The powerful solution integrates Nokia Digital Automation Cloud (DAC) and Nokia MX Industrial Edge with DXC Platform X™, offering organizations high-bandwidth, low-latency wireless networks with high capacity edge compute on-premises.

Result: The powerful solution supports increased automation, enhanced flexibility, operational technology (OT) data processing.

Use case: Kyndryl and Nokia will launch a partner innovation lab in Raleigh, North Carolina, to bring advanced wireless connectivity and edge computing, integrated with a multi-factor zero trust model, converging IT and OT for enterprises

Through the collaboration, a multi-factor zero trust model for industrial networking is enabled at both the IT and OT sides of the network using the best tools and resources from each of the companies.

Result: To date, Kyndryl and Nokia have successfully implemented a private wireless network with edge computing for Dow, at its petrochemical processing plant in Freeport, TX. The modernization of the Dow plant with advanced connectivity has increased worker safety, and enabled remote audio and video collaboration, and real time smart procedures.

Use case: Bosch Rexroth is onboarding its ctrlX Operating System onto Nokia MX Industrial Edge, making it widely available to Nokia MXIE customers as an easy click-to-deploy application on a fully orchestrated OT edge platform.

For customers running ctrlX OS on Nokia MX Industrial Edge will give them access to high capacity computing with GPU, enabling new I4.0 use cases that require a new level of rich sensing

Result: Improvements in operations, commercial simplicity and efficiency are possible thanks to the addition of ctrlX OS running on Nokia MX Industrial Edge

Resources

Find more

Talk to a Nokia expert

Please complete the form below.

The form is loading, please wait...