- Overview

- Quote

- What is industrial AI?

- How can AI superpower your industrial workforce and operations?

- Industrial AI needs masses of real-time, relevant data

- Trusted by industries globally

- How to empower your digitalization and AI journey?

- Digitize

- Contextualize

- Optimize

- Autonomize

- Why Nokia?

- Resources

Unlock the transformational power of Industrial AI

Connect, contextualize and utilize data to superpower your workforce and operations

From automating key processes to detecting site anomalies in real-time and enabling deep situational awareness, AI has the potential to transform efficiency, agility and sustainability across your operation. Having always-on access to high quality, real-time OT data is integral to successful digitalization and unlocking the extraordinary things that industrial AI can do. But is your data infrastructure ready for it?

A recent report by Market Research Future shows that the Industrial AI market is projected to grow from USD 6.35 billion in 2025 to USD 191.76 billion by 2034 – and industrial leaders are taking action. For example, 95% of manufacturers plan to invest in AI/ML, Gen AI or causal AI in the next five years, or already have.

But to successfully create an AI-powered industrial operation, it takes infrastructure that establishes a solid technology foundation of data collection, aggregation and harmonization. Deloitte’s recent report shows that enterprises today are investing in creating this foundation, including sensors, edge computing, cybersecurity and analytics, to set themselves up for success in the next step of creating smarter, safer and more intelligent operations. The priority is clear: unlocking the transformational powers of AI starts with building the right digital infrastructure, technical enablers and data capabilities.

What is industrial AI?

Industrial AI applies artificial intelligence across industrial sites, creating a ‘digital industrial brain’ that constantly monitors operations, building data-driven intelligence. Once trust is built in, the “brain” can then enable automated decision-making and intelligent automation with incredible scale, speed and precision, while maintaining the deterministic levels of latency, availability, reliability and data security needed in an OT environment.

It’s already delivering significant benefits. Right now, AI is superpowering how industrial enterprises such as manufacturers, ports, mines and utilities operate and what workforces can do:

- Gaining contextual awareness from real-time operational data

- Creating actionable insights

- Transforming workflow efficiency

- Predicting issues before they happen

- Starting to enable autonomous decision-making

How can AI superpower your industrial workforce and operations?

Industrial AI needs masses of real-time, relevant data

Data is increasingly pivotal as the power of AI comes to the fore as an essential foundation of Industry 4.0 - but AI is only as good as the data you feed it. Realizing AI’s value at scale demands real-time, complete and contextualized data – and data siloes are often the enemy within. ABI Research also found that just 5% of industrial data is currently processed to deliver insights or support value-added use cases. Legacy systems often capture only the data required to keep machines running, rather than enabling holistic monitoring and analytics. The data that is collected is typically siloed, manual, and difficult to integrate across systems, making real-time visibility and data-driven optimization nearly impossible.

That’s why the next wave of digital transformation is accelerating and superpowering digitalization journey by combining edge computing and AI as a service with business-critical connectivity, through an open industrial edge platform. The result is enterprises’ ability to connect, harmonize and secure data from across their sites, turning fragmented and complex data streams into operational intelligence and actions.

Trusted by industries globally to enable their digital foundations

Nearly 1000 enterprises around the world trust our technologies to enable their digitalization foundations - so they can connect, harmonize and secure data from across their sites, and turn complex data streams into actionable insights.

Our heritage of innovation in connectivity, coupled with a robust partner ecosystem, ensures that your digitalization journeys are in the safest of hands – with industry-leading expertise, future-ready data infrastructures, and real-world application experience.

How to empower your digitalization and AI journey?

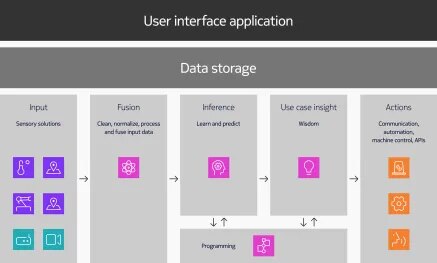

Digitizing your physical assets, contextualizing diverse data, optimizing with real-time insights, and enabling intuitive automation are critical steps to unlocking the full potential of industrial AI. Our Nokia edge compute and AI platform supports you at every stage of this journey: with 4G/5G private wireless and industrial devices to connect workers and machines, an on-premises industrial edge to create a unified data lake and process data in real time, and a catalogue of industrial applications from Nokia and leading ecosystem partners. Crucially, by residing on your premises, our platform ensures that critical OT data remains on-site, maintaining full data sovereignty and security. Explore each step of the journey below to see how we help turn your data into action.

Digitize

Get real-time data from physical assets

The first step to unlocking the value of industrial AI is generating usable, real-time data from all your physical assets. That starts by connecting machines, devices and legacy systems – then centralizing and harmonizing OT data at the industrial edge to create a single source of truth for your entire OT environment.

IoT sensors, handhelds, field routers and other industrial devices play a vital role in capturing comprehensive OT data from machines, workers and legacy systems. Pairing this data capture with deterministic, pervasive, high-bandwidth wireless connectivity enables continuous, automated, real-time data collection across your operation.

Our portfolio of ruggedized and/or EX-protected devices includes everything from modems, routers and dongles to phones, tablets and cameras, helping you connect your workforce, sensors and machines in harsh industrial environments.

Nokia DAC Private Wireless 4.9G/LTE and 5G can reliably connect everything 24/7 across your vast industrial site – it’s purpose-built for the scale, mobility and reliability demands of business- and mission-critical OT operations.

The security of digitalization technology is a clear priority for industrial players because it’s integral to maintaining smooth operations, protecting reputations and retaining the proprietary sovereignty of data.

ABI Research has identified that “Private networks are easily the most secure form of connectivity, and players can ride on this demand for safer systems - especially for applications such as mission-critical communication, heavy machinery automation, and supply chain systems.”

The right combination of industrial applications from both Nokia and our ecosystem partners, deployed on our MX Industrial Edge, lets you effectively manage IIoT assets. You can ensure zero trust security at the industrial edge and advanced operational site perimeter security with virtualized next generation firewalls while always looking for and closing down IIoT device vulnerabilities.

Industrial digitalization embraces the entire industrial process across your business, from resource extraction, through to supply chain management and production and the delivery of goods to your end customers. At an enterprise level, this requires IT/OT convergence, letting you effectively harness OT data to measure KPIs and compliance targets, while also promoting automation throughout the data lifecycle.

As part of the ecosystem environment on the Nokia MX Industrial Edge, Crosser Node, Litmus Edge, Prosys OPC UA Forge and the Nokia Integrated Operations Center complement our 4.9G/LTE and 5G Private Wireless connectivity. They unify data collection, normalization, contextualization and analytics from a single data lake at the edge with nearly 300 pre-built device drivers and integrations for OT assets and enterprise systems.

Contextualize

Turn digital data into insight and knowledge

Industrial AI has become more than just a buzzword. It’s now a real way of working, providing real-time data analysis for situational awareness, operational intelligence and building more efficient workflows. Machines and systems learn from data, predict issues before they happen and optimize operations at a scale and speed that, until recently, wasn’t possible.

Gen AI-powered solutions can streamline operations through natural language processing, enabling more intuitive human-machine interactions, and improving efficiency in complex industrial environments.

Nokia MX Workmate is industry's first OT-compliant, generative AI solution for connected workers. It can answer queries and send real-time contextual information to workers using natural sounding, easy to understand, human language generated by Gen AI. This is achieved through APIs that open communication with key applications.

Gathering visible, real-time universal insights enables you to achieve data-driven operational excellence and put augmented and automated decision-making approaches in place. Both are key to realizing your business goals using Industry 4.0.

Our OT Edge DataOps solution can help you harness and leverage data to support daily decision-making at every level of your business – ensuring that the right people and machines have access to the right information at any given moment. It achieves this by enabling comprehensive data collection, aggregation and harmonization from various assets and resources close to the data source, giving you a holistic understanding of your operations.

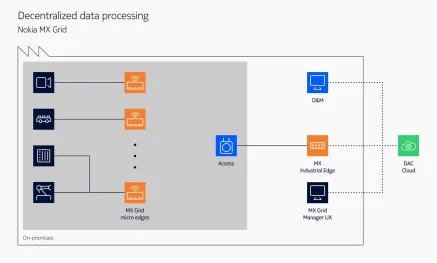

Some advanced industrial use cases such as real-time AI-based video analytics for worker safety or production quality control and ultra-low latency automation for mission-critical operations demand that massive data volumes are processed at extreme speeds. In these highly time-critical scenarios, a single, central, on-premise edge may not be fast or close enough to deliver all your OT performance requirements. Decentralized hyperlocal data processing is the answer.

Nokia MX Grid puts a pool of distributed micro-edges in place that bring compute power and AI capabilities right to the data source. AI/ML models run on the micro-edges to pre-process high-volume data streams, sending only relevant insights to the central edge, Nokia MX Industrial Edge (MXIE). This reduces latency and bandwidth use while enabling the faster decisions and automated responses you need.

Optimize

Turn insights into value-driven actions and impact

Once you have real-time, contextualized data and a clear view of inefficiencies and bottlenecks, the next step is turning data insights into action and impact. By layering industrial applications on your edge infrastructure you can resolve issues, optimize workflows and boost productivity. AI-powered tools like digital twins and predictive maintenance also help shift your operation from reactive to predictive, preventing issues before they impact safety, performance or output.

Now you have access to real-time OT insights you can deploy business-critical applications that can drive measurable improvements across your end-to-end operations. Because our unified OT edge compute and AI platform is ecosystem-neutral, you can deploy our own range of in-house applications as well as edge workloads coming from many leading software vendors, enabling concrete Industry 4.0 use cases with a fast ROI.

Our industrial application portfolio supports a wide range of use cases helping you to meet key operational goals – from enhancing situational awareness and workforce efficiency to reducing safety risks and lowering environmental impact.

Intelligent camera-based positioning and object detection transforms video feeds into real-time operational insights. From detecting safety risks to tracking assets and spotting defects, they reduce manual workloads, speed up response times and enable smarter automation across industrial sites.

Using real-time video feeds and AI-powered vision analytics, Nokia Visual Position and Object Detection enables real-time tracking and positioning without the need for physical tags. It can be trained to detect anything on-site, making it a key enabler for improved worker safety and the location tracking of critical industrial equipment.

One of the most exciting trends in industrial digitalization today is sensor fusion, enabling intelligent decision-making close to the controlled asset. By integrating data from multiple sensors in real time, this approach provides far more accurate, reliable and comprehensive contextual awareness than is possible from accessing data from each sensor independently.

Integrated with our edge compute and AI platform, Nokia MX Context combines multimodal sensor fusion and AI inferencing to integrate OT data from different sources. This unleashes actionable insights, predictive recommendations and new possibilities for intelligent automation in key Industry 4.0 use cases such as worker safety and asset tracking.

Autonomize

Turn operational wisdom into intuitive, self-optimizing industrial operations

Increasingly, AI-powered campuses are being augmented by industrial brains that continuously collect and analyze data from thousands of sensors and processes, using it to make recommendations and tweaks at a scale humans alone cannot match. The result is improved efficiency, reduced energy usage and costs and better decision-making that allows workers to focus on more strategic tasks.

As AI matures and operations become increasingly complex, autonomous systems can take industrial performance to the next level. By combining real-time data with AI and ML models, you can power self-optimizing processes that respond instantly to changing conditions, improving efficiency, reducing manual intervention and increasing resilience.

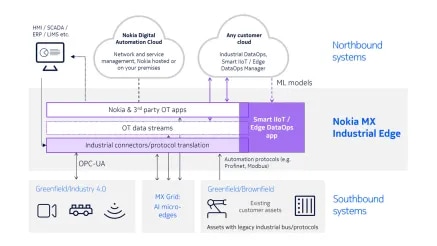

Our Nokia edge compute and AI platform supports this with a broad set of southbound connectors, enabling seamless integration with industrial automation systems. This tight integration ensures real-time interoperability between IT and OT systems, allowing AI models to not only detect issues, but also to act on them, powering closed-loop, autonomous decision-making.

To truly superpower your workforce and operations, insights generated at the edge must be accessible to all relevant users – not only within a single operation, but also across multiple sites.

Centralizing and integrating OT data with enterprise IT systems ensures that everyone, from frontline teams to business leaders, can make decisions based on a shared, real-time view. This enables better cross-site collaboration, enterprise-wide visibility and smarter strategic decision-making from operations to supply chain and business planning.

Our Nokia edge compute and AI platform offers robust northbound integration with cloud platforms and enterprise IT systems, enabling seamless, secure data flow to feed real-time intelligence to the point of need, whether that’s AI applications, the local workforce or business decision-makers. With instant operational insights, they can act swiftly, and drive coordinated, data-driven outcomes.

By leveraging augmented reality and spatial computing technology, you can improve operational workflows, efficiencies and workplace safety. Workers can complete complex tasks more efficiently and safely than ever before with critical work instructions presented clearly on a tablet, mobile device or heads-up display.

Imagine a factory worker posing an urgent downtime query using their tablet and instantly getting step-by-step instructions on what the problem is and how to solve it. Meanwhile, that same device continuously monitors its surroundings, providing contextual and situational data to predict related bottlenecks, and even keep its human operator safe.

How can AI be successfully deployed in industrial environments?

Partner Nokia. We create technology that helps the world act together

A heritage of innovation in connectivity

With Nokia, you get a trusted partner with deep roots in industrial-grade connectivity and a proven track record of enabling digital transformation at scale. Our MX Industrial Edge (MXIE) ensures your data remains secure, sovereign and on-site, giving you full control while unlocking real-time intelligence. Backed by decades of leadership in communications technology and the pioneering innovations of Nokia Bell Labs, we help industrial enterprises solve today’s most pressing challenges while laying the foundation for what’s next – from AI to digital twins and autonomous operations to Industry 5.0.

A robust partner ecosystem

Digitalization excellence doesn’t happen in isolation. We collaborate with a broad ecosystem of trusted partners, from application and device specialists to industry domain experts, to plan, build and deploy technology solutions that deliver measurable business value. Through long-standing relationships with leading system integrators, we ensure that any new solutions seamlessly integrate into your existing operations and IT/OT environment. By leveraging our combined deep industry and technology expertise, we can help you realize your digitalization and AI ambitions.

Leading industrial enterprises trust us

With Nokia, your digital foundation and your AI ambitions and investments are in the safest hands. We’re trusted by customers around the world across industries spanning manufacturing, transportation, energy, mining, ports and many more to deliver future-enabling infrastructures.

We’re the recognized, uncontested market leader in private wireless LTE and 5G technologies, trusted by 920+ private wireless customers* and accounting for about 50% of this fast-growing market. Nokia is also the only company recognized as a ‘Champion’ Market Momentum Leader in Omdia’s 2025 Private 5G Market Radar report, congratulated for “jump starting the market to explore opportunities in the mission-critical edge where the connectivity at OT world is merging”.

* June 2025

Find out how we can help you to superpower your industrial AI and digitalization journey, unifying your data to start unlocking the transformational powers within it.

Please complete the form below.

The form is loading, please wait...