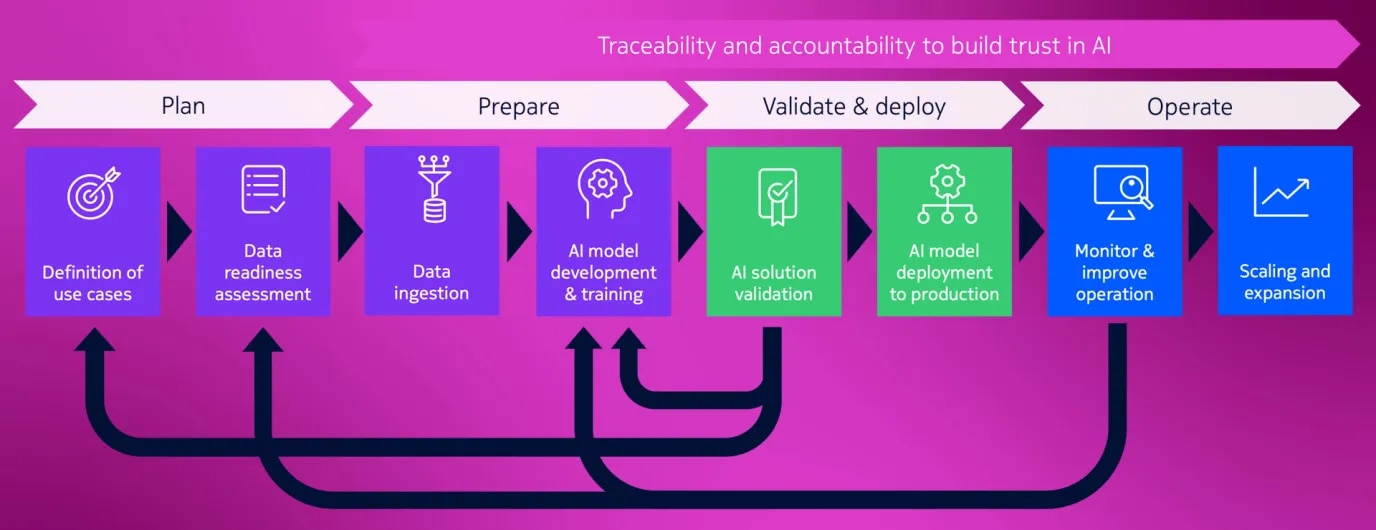

- What AI use cases should I adopt?

- How can I assess data readiness?

- How is data ingestion handled?

- How can I build and train AI models?

- How do I pilot and validate AI?

- How do I deploy the AI model?

- What monitoring and process improvements should I implement?

- How can I scale AI across operations?

- AI deployment for industry in a nutshell

- Related Nokia AI solutions

- Resources

How can AI be successfully deployed in industrial environments?

The Industrial AI market is projected to grow from USD 6.35 billion in 2025 to USD 191.76 billion by 2034, at a remarkable compound annual growth rate (CAGR) of 46.20%, according to a recent Market Research Future (MRFR) report.

AI is a key technology enabler of Industry 4.0. It will help transform industrial and operational technology (OT) environments to unlock new levels of productivity, efficiency, safety and sustainability.

Realizing AI’s potential for industry requires a strategic approach, combining structured deployment with the right enabling technologies. The benefits are significant, but successful implementation hinges on careful planning to navigate challenges and avoid common pitfalls.

This guide is designed to answer your questions with a practical, step-by-step framework for successful AI adoption in industrial environments.

What AI use cases should I adopt?

Identify high-value AI applications that align with your operational goals. Significant benefits can be realized in the following industrial use cases:

How can I assess data readiness?

Modern industrial environments increasingly rely on data-driven operations to enhance decision-making, optimize processes, and realize AI’s full potential. To ensure high-quality, relevant OT data, you should implement:

Connectivity solutions

A reliable, low-latency communication layer, such as private LTE/4G or 5G, to support real-time collection of large volumes of OT data from the shop floor.

On-premises edge

An on-premises edge processor, a critical component of the Data Pipeline/DataOps framework, to rapidly aggregate, normalize, harmonize and contextualize large volumes of operational data, making it available for consumption across multiple AI use cases.

How is data ingestion handled?

Once data pipelines are in place, the focus shifts to real-time ingestion of OT data into the AI processing environment using message brokers such as MQTT, following a Unified Namespace (UNS) structure. Here, filtering, buffering, and lightweight pre-processing clean, synchronize, and deliver the data at the required frequency for AI applications.

Decentralized and orchestrated processing capabilities delivered using lightweight edge nodes play a key role in the initial filtering, tagging and compression of data, while processing it close to the source to support those use cases that require immediate response or local decision-making.

Distributed processing is critical for timely data ingestion and for maintaining AI model accuracy, responsiveness and scalability.

How can I build and train AI models?

AI algorithms must be created to perform tasks such as anomaly detection, failure prediction, or pattern recognition on historical and real-time industrial data using machine learning frameworks such as TensorFlow or PyTorch.

Data is fed into the AI model, allowing it to learn, recognize patterns, make predictions and continuously fine-tune internal parameters to minimize errors and improve accuracy.

How do I pilot and validate AI?

Before full-scale deployment, you must test your AI solution in a controlled environment that closely simulates actual industrial conditions. During testing, you should:

Identify gaps

Measure the AI system’s impact on key performance indicators such as accuracy, reliability, and response time to identify any gaps, biases, or unexpected behaviors in the model.

Improve performance

Gather feedback to refine and fine-tune AI algorithms to improve performance and robustness.

Identify operational challenges

Assess integration with existing OT systems and workflows to identify operational challenges and verify that the solution meets safety, compliance, and business requirements.

How do I deploy the AI model?

Deploy the validated AI model into the live production environment by integrating it with existing industrial systems, ideally using an Edge DataOps approach, and ensure it operates reliably under real-world conditions while delivering real-time actionable insights.

What monitoring and process improvements should I implement?

Proactively track performance to ensure the AI model remains accurate and effective in the long term.

Implement drift detection

- Leverage user feedback and changes in data distribution or model performance to identify any performance degradation.

- Use this data to retrain or update the model for optimal results and to adapt it to changing conditions.

Maintain auditability, traceability and compliance

- Trust in AI decisions is vital, particularly in safety-critical or heavily regulated environments. Ensure all actions and data flows are logged and reviewable within a robust governance framework, supporting relevant compliance and responsible practices.

How can I scale AI across operations?

After testing and validation, you can replicate success by deploying your AI solution across sites and departments, continuously exploring and integrating new use cases to maximize overall business value and operational impact.

AI deployment for industry in a nutshell

Long-term successful AI deployment for industries requires:

- A clear strategy

- The right enabling technologies, including robust data pipelines, on-premises edge computing, reliable wireless connectivity and MLOps platforms

- A comprehensive employee training program

- Ongoing monitoring to address data security, privacy, integration challenges, ROI, necessary skillsets and ethical considerations

Following this structured approach, you can effectively harness the power of AI to improve safety, boost efficiency and drive the sustainability of your industrial operations.

Related Nokia AI solutions

Unlock the transformational power of Industrial AI

Connect, contextualize and utilize data to superpower your workforce and operations.

Resources

Talk to a Nokia expert

Please complete the form below.

The form is loading, please wait...